In today's highly advanced world of technology, the art of 3D printing has gained popularity like never before. This technology has made it possible for humans to create almost anything they can imagine. Whether it is toys, art pieces, or even mechanical parts, 3D printing has reshaped the way we think about manufacturing and production.

One of the integral components of a 3D printer is the industrial extruder. It is the device that converts raw materials, such as plastic or metal filaments, into a molten substance that is used to create the final product. This article discusses the importance of the industrial extruder in 3D printing and how it has simplified the manufacturing process.

What is an Extruder?

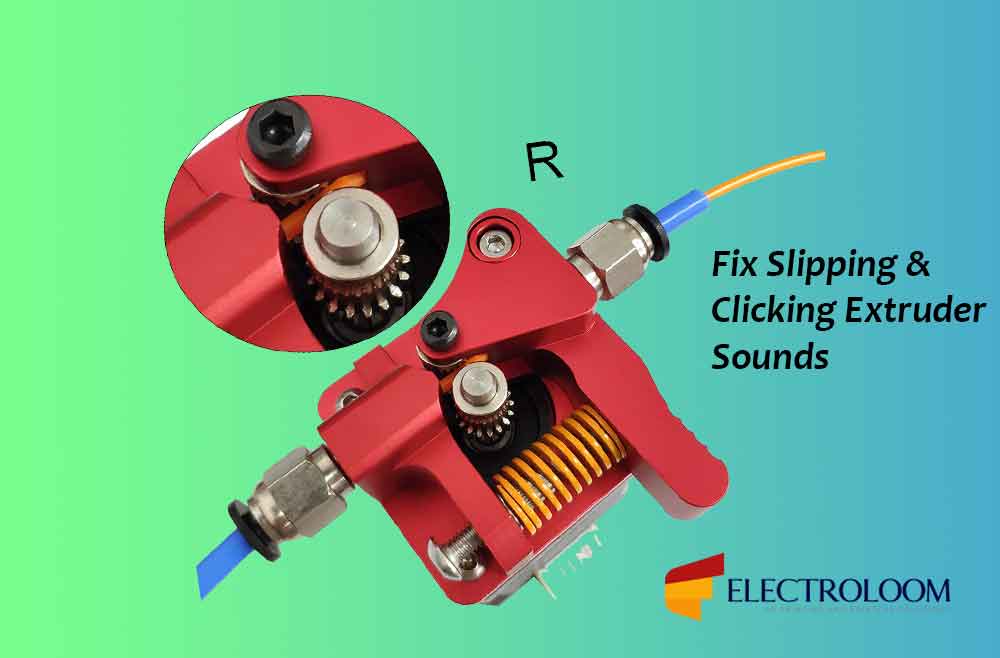

An extruder is a device that is responsible for delivering the raw material, typically a plastic or metal filament, to the printhead of a 3D printer. Once the material reaches the printhead, it is then heated to a melting point before being extruded, allowing it to become malleable and pliable, ready to be shaped.

The extruder is a critical component that plays a pivotal role in the 3D printing process. It is responsible for ensuring that the raw material is accurately fed to the printhead, at the correct temperature, ensuring the proper consistency and layer-by-layer bonding of the final product.

The Importance of Industrial Extruders

Industrial extruders are high-torque devices that are designed to handle large amounts of raw material, which is a critical requirement in the manufacturing process. They are equipped with top-quality heating systems that allow materials to be melted at a high temperature, subsequently producing high-quality products.

Industrial extruders have revolutionized the 3D printing industry. They have helped to streamline the manufacturing process and have made the development and production of complex products possible. These types of extruders can handle a range of different materials, including plastics, composites, and metals, opening up a whole new world of possibilities in the world of 3D printing.

The Benefits of Using Industrial Extruders

The following are some key benefits of using industrial extruders in the 3D printing process:

High throughput capacity: Industrial extruders can handle a large volume of materials, which means they are ideal for large-scale production.

Greater consistency: Industrial extruders are equipped with advanced control systems that produce consistent quality outputs, reducing the potential for variability and defects.

Improved efficiency: Industrial extruders have efficient cooling systems that allow them to produce high-quality products faster.

Versatility: Industrial extruders can be customized to handle a range of different materials, providing manufacturers with flexibility and increasing the range of products they are capable of producing.

Cost savings: By using industrial extruders, manufacturers can save on the cost of materials and labor since these devices allow for faster manufacturing time than traditional methods.

Conclusion

Industrial extruders have revolutionized the 3D printing industry by allowing manufacturers to produce complex products with accuracy and precision. These devices have made the process of production faster, more efficient, and cost-effective, ultimately reducing the time and cost associated with manufacturing. As technology advances, it is clear that the importance of industrial extruders in 3D printing will continue to grow, opening up a limitless range of possibilities and opportunities for manufacturers worldwide.